SEAM WELDING MACHINE & STEEL PLATE TWO ROLL BENDING MACHINE

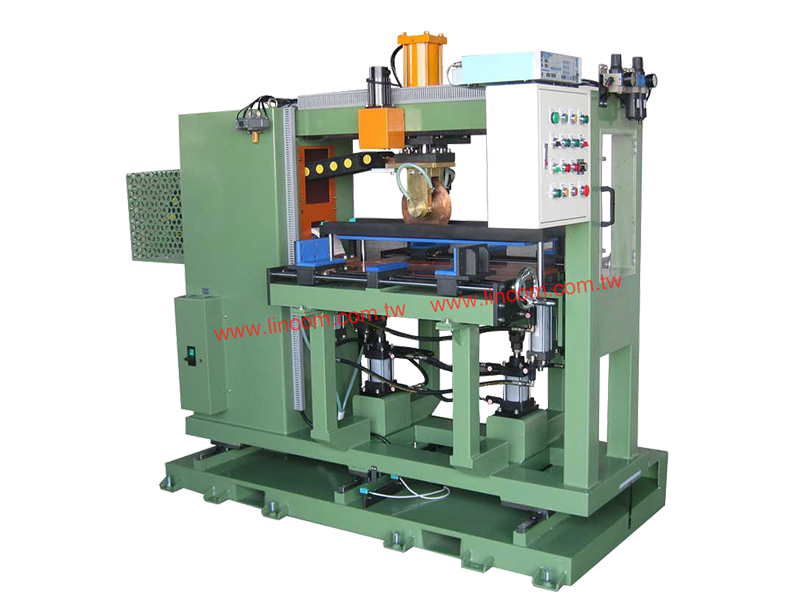

SEAM WELDING MACHINE

Welding Finishing: Low defect rate, heat deformation and oxidation phenomenon is less seen, which saves subsequent processing procedures.

Stability: Small welding tolerance range, high precision to meet JIS vehicle standards.

Economy: Economic price for consuming spares such as copper-alloy electrode and low power consumption saves much operation cost.

High Flexibility: The machine is suitable for either thin or thick workpieces. Available in both continuous type and pulse type of electricity discharge.

Smooth Finishing: No soldering scars which saves lots of time for polishing, soil patching and coating.

Simple Operation: The machine can start welding once the power switches on. Easy operation that allows technician to get on hand fast.

Automotive fuel tank, oil barrel, oil can, automotive muffler, exhaust pipe, motorcycle rim, stainless steel water tank, air conditioner air pipe, solar panel, cartridge box, sprayer barrel, washing machine dehydration tank, water bucket, electric kettles, thermos bottle, filter, wine barrel, transformer, motor outer shell, net planar welding, stainless steel planar welding, kitchen utensils.

| Model | Rated capacity | Rated primary voltage | Rated frequency | Weld current | Roll-spot capacity stainless |

| KVA | V | Hz | A | mm+mm | |

| LSW-80 | 80 | 220/440 | 50/60 | 18000 | 0.8+0.8 |

| LSW-100 | 100 | 21000 | 1+1 | ||

| LSW-120 | 120 | 24000 | 1.2+1.2 | ||

| LSW-150 | 150 | 27000 | 1.8+1.8 | ||

| LSW-200 | 200 | 31000 | 2+2 | ||

| LSW-250 | 250 | 35000 | 2.2+2.2 | ||

| LSW-300 | 300 | 38000 | 2.4+2.4 |

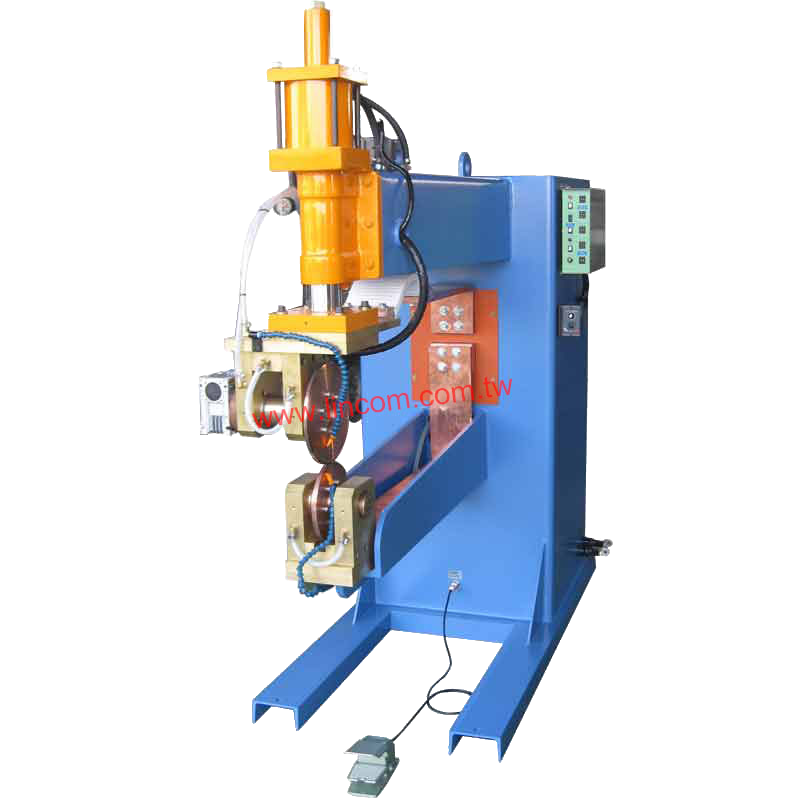

Vertical Seam Welder

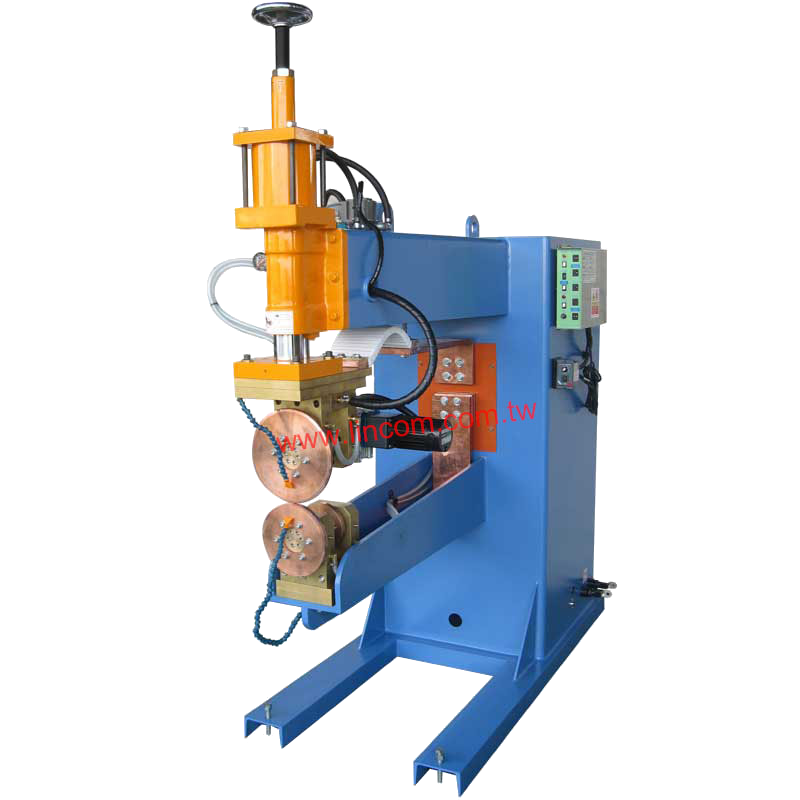

Horizontal Seam Welder

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

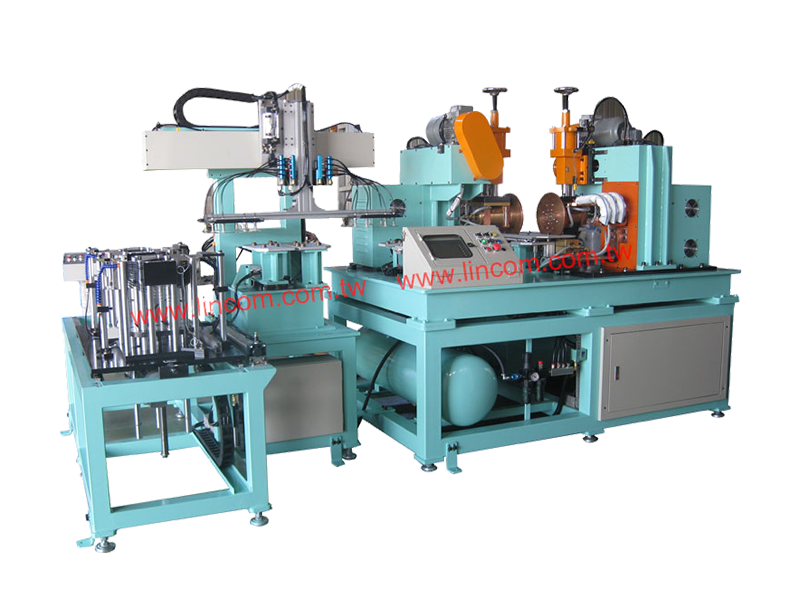

Seam Welding Fully Automation Design

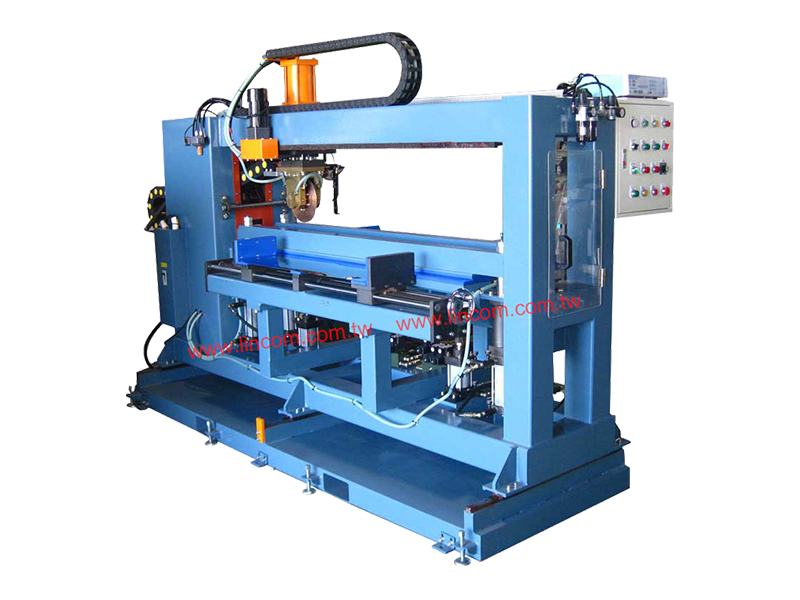

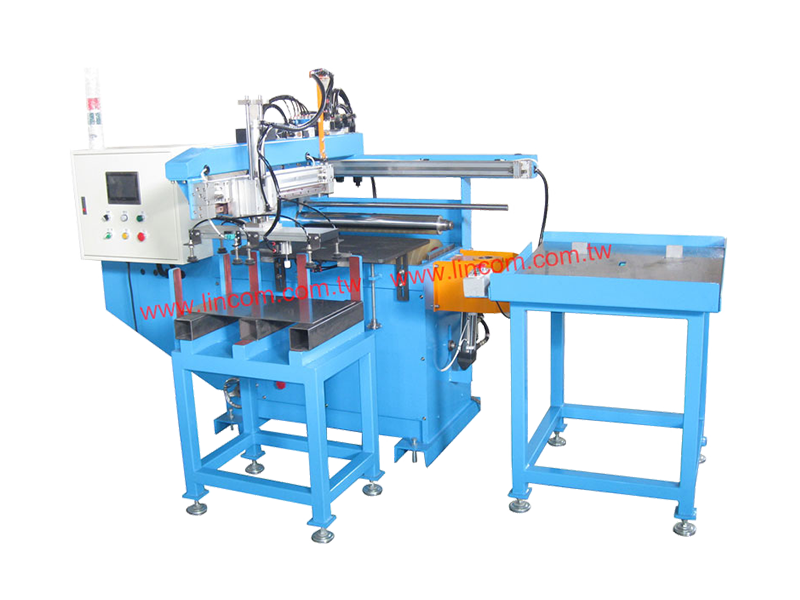

Steel Coil End Joint Seam Welder-1230

Steel Coil End Joint Seam Welder-800

X-Axle Rotating Seam Welder

| ※Remarks: | 1.For details please contact us. 2.Customers specific requirement are Welcome! |

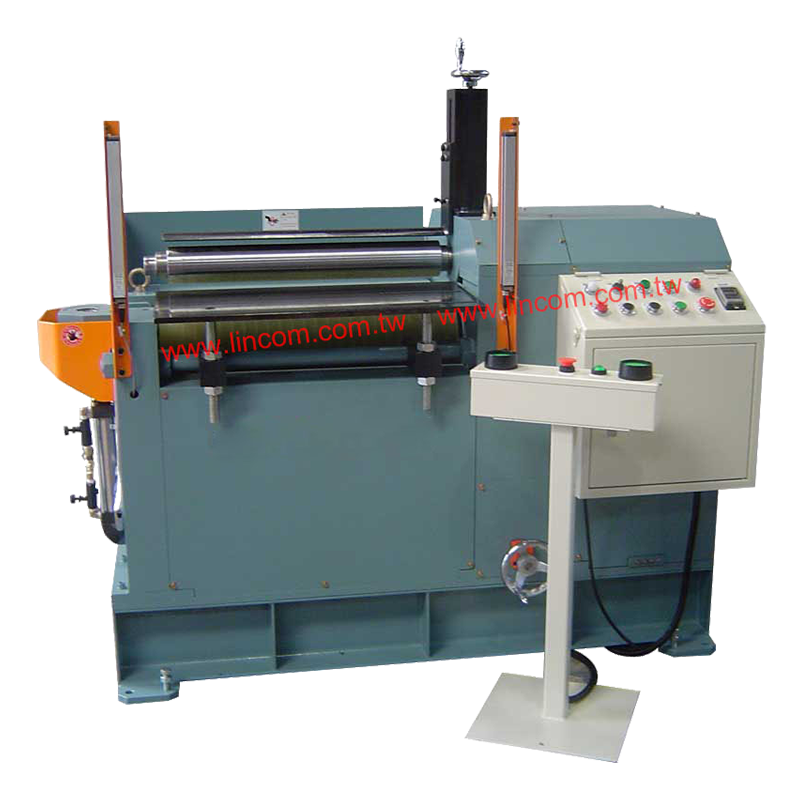

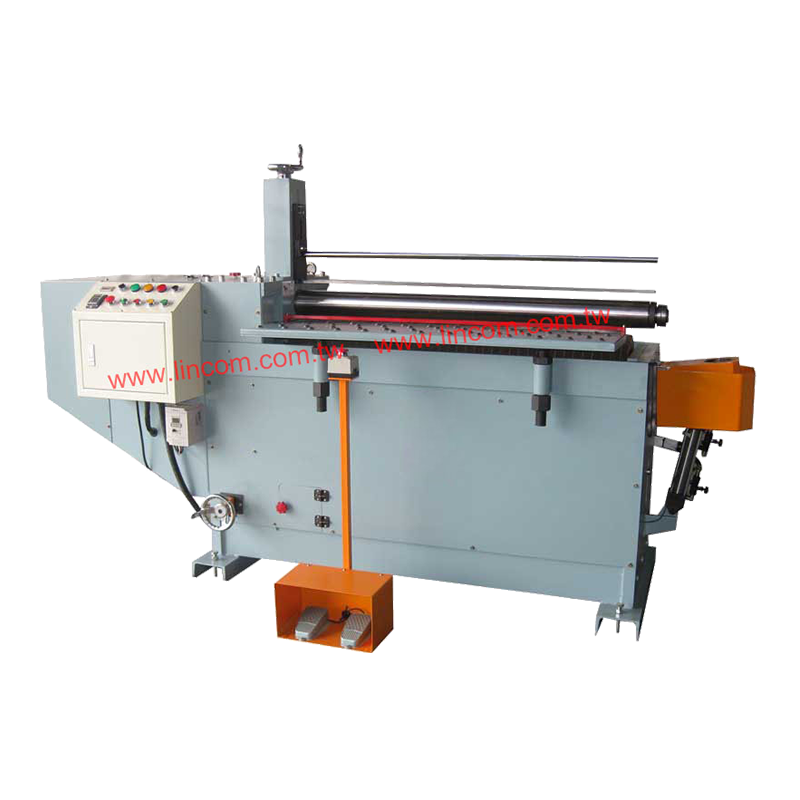

STEEL PLATE BENDING (ROLLING) MACHINE, Two Roll Type

* This Hydraulic Rolling machine is applicable for round and taper pipe. For our standard models, the effective rolling length is 600-1600mm, rolling thickness is 0.3-4.0mm (stainless steel to 2.5mm), but we do accept customer's special requirement, according to the required length and diameter, we select the suitable model and add supplemental supporting base.

* This machine adopts dual shaft structure and by hydraulic system rolling for strong and even power force.

* Roller material is rubber, it is wear resistant and provides long service life, also it avoids scratches on the workpiece surface.

| Model | Effective rolling length |

Rolling thickness |

Driving motor |

| LPR-600 | 600mm | SS41 0.3~4mm SUS 0.3~2.5mm |

AC motor |

| LPR-800 | 80mm | ||

| LPR-1000 | 1000mm | ||

| LPR-1300 | 1300mm | ||

| LPR-1600 | 1600mm |

| ※Remarks: | 1.Right of modification reserved. 2.Customers specific requirement are Welcome! |

Steel Plate Two Roll Bending Machine

Two Roll Bender for Ducting-1300

Ducting Pipe Welding Machine

Hydraulic Taper Bending(Rolling) Machine,Special Type

Steel Plate Auto Bending (Rolling) Machine with Auto Feeding System

※Customers specific requirement are Welcome!